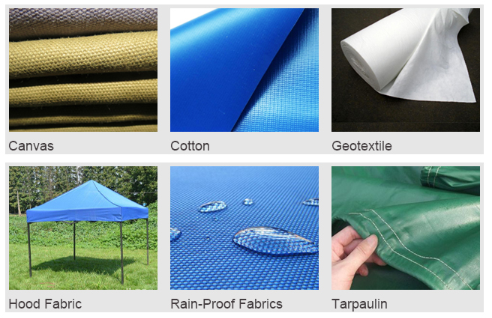

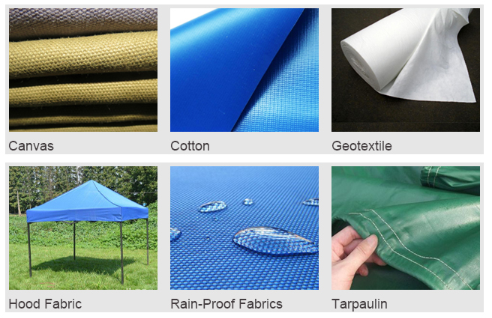

Hydrostatic Head Tester, used for determining the resistance of fabrics (canvas, coated fabrics, cover cloth, rainproof clothing fabrics, and geotextile materials) and films to water penetration under pressure while firmly clamped in the test rig of standard area.

BRAND | Great Win |

ITEM NO. | GW-163C |

ORDER(MOQ) | 1 |

PAYMENT | TT OR L/C |

PRODUCT ORIGIN | China |

SHIPPING PORT | Shenzhen Port |

LEAD TIME | In stock, 7days Fast Delivery |

Standard

AATCC 127 ISO 811 ISO 1420A EN 20811

EN 1734-1996 BS 3321 DIN 53886 ERT 120-1

ERT 160-0 GB/T 4744 JIS L1092 B-b AFNOR GO7-057

· Closed-loop controlled servo motor drives pistons to achieve the unique water pressure raising rate balance system.

· The variable test method can be selected, test time and variable pressure increasing rate can be set and saved.

· Wide range of pressure increasing rate and freely adjustable. Pressure increasing system is adjusted by the dynamic feedback to prevent overload.

· Real-time test results are shown on the large colourful touch panel.

· Test results can be made up to a report on software and print out directly.

· 5 test methods are included

Pressure raising mode, Constant-pressure mode, Constant pressure & fixed time mode, Extending-relaxing mode, Water penetration, and leakage mode.

· Equipped with a LED lamp to observe the test process clearly.

· Pressure Range

0 ~ 200kPa (20 m water column).

0~ 500kPa (50 m water column).

0 ~ 1000kPa (100 m water column).

· Increasing rate of water pressure 1 ~ 60kPa/min stepless adjustable

· Units Pa, kPa, mmHg, cmH2O

· Automatic clamp with holding force 5kN

· Standarad Test Head 100cm2 (7.8cm2 optional)

1: The test time can be changed arbitrarily during the test

2: The test stops and automatically opens the mold

3: All graphics can be set in different units (Ib-in kg-cm N-m dN-m)

4: The software supports traditional Chinese, simplified Chinese, and English

5: Easy to operate, users can automatically test and archive automatically without touching the computer

6: Each control interface including curve, coordinates, background color can be set freely

7: The existing vulcanization curve can be compared with the previous vulcanization curve at the same time or separately, and each curve can be set with different colors for comparison

8: The test data has a variety of query functions, which can be searched by time, date, rubber name, shift, operator, test temperature, and other test conditions

9: The test data is stored in a database, with multiple data export methods, export to, PDF, EXCEL and other document functions

10: With the upper and lower limit qualified value on the setting report, the software automatically judges whether it is qualified

11: Can print all kinds of graphics on a report at the same time

12: Software and hardware automatic detection function, convenient for maintenance and repair

13: The number of data sampling is high, and no important data will be missed

14: High-precision temperature control system to ensure stability and temperature recovery speed

15: Adopt a fixed eccentric wheel structure to provide an extremely stable shear angle to ensure test accuracy

16: The high-precision torque sensor is installed close to the upper mold, and the upper mold cavity measures the torque, and the torque value is accurate and stable

Weight

| 130KG |

| Power | 220/110 V 50 Hz 200W |

| Dimensions | 560x400x600mm (L x W x H) |